Location: SMAM4SoRo – Department of Mechanical, Mathematics and Management – Politecnico di Bari

Centro Interdipartimentale TTEC Taranto – Politecnico di Bari

Lab head: Prof. Ing. Gianluca Percoco

Contact: gianluca.percoco@poliba.it

Lab Team

Gianluca Percoco

Lab Head

Gianni Stano

Assistant professor

Alessio Pricci

Post-doctoral researcher

Angelo Paradiso

Lab Technician

Antonio Pavone

Post-doctoral researcher

Rosanna Rifino

PhD student

Luca Di Leo

PhD student

Iqbal Muhammad Saqlain PhD student

Lab Mission

The SMAM 4SoRo (Sustainable Materials and Additive Manufacturing for Soft Robotics) Lab was established in 2022 as part of the EU-funded BRIEF project.

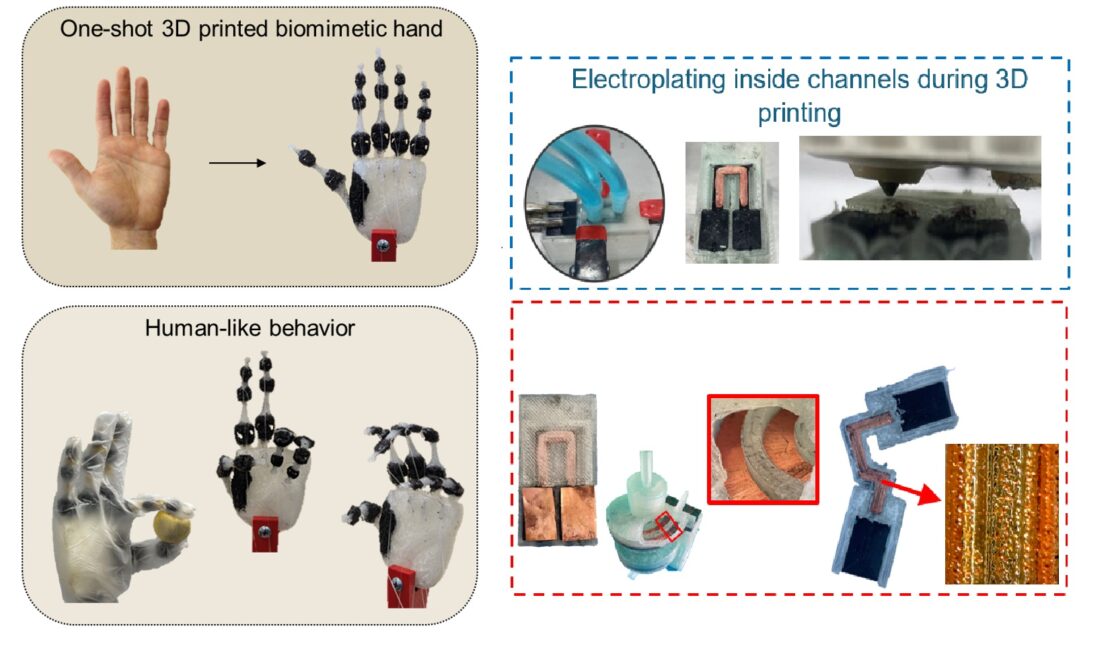

The lab focuses on leveraging Additive Manufacturing technologies to advance the fabrication of functional soft and bio-inspired devices by jointly processing multiple materials, ranging from rigid to extremely soft and electrically conductive.

Unconventional and ultra-soft materials are studied and combined to develop high-performance soft robots using state-of-the-art 3D printing systems equipped with custom-built mechanisms to enhance final part performance such as layer by layer adhesion, soft-stiff adhesion, void reductions,and soft robot capabilities.

A core objective of the SMAM 4SoRo Lab is to deepen the understanding of the widely used Material Extrusion 3D printing technique through process simulations and machine learning-based approaches.

Additionally, sustainability is one of the main goals pursued at the SMAM 4SoRo lab, both in terms of materials and processes, through the use of custom recycled materials and custom-designed 3D printing machines. ” This machine is used to create sustainable materials by recycling waste generated during the 3D printing process“.

SMAM 4SoRo is also defined by its strong international collaboration network, as demonstrated by multiple joint publications and projects with renowned institutions including: The University of Texas at Dallas, Baylor University, Vrije Universiteit, Nottingham Trent University, The University of Texas at El Paso, KU Leuven, Deakin University, Universidad Carlos III de Madrid, and School of Advanced Studies Sant’Anna of Pisa.

Devices

[CAPABILITIES AND EQUIPMENT AT SMAM 4SoRo LAB]

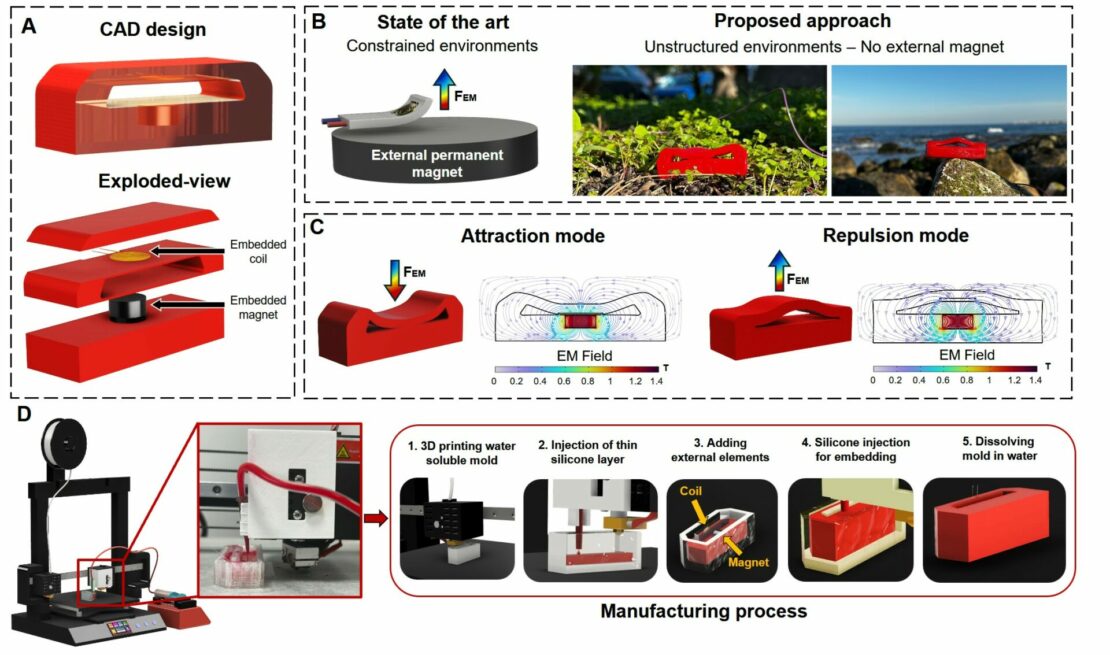

Finding new additive manufacturing approaches to advance the fabrication of soft bio-inspired robots with embedded sensors and actuators, as well as 4DPrinted smart structures, is the ultimate goal of the SMAM 4SoRo Lab research group.

The major equipment used to perform such multidisciplinary research are:

Multi-Material Extrusion #3Dprinters: 3D printers with multiple heads, capable of jointly extruding two materials at the same time (i.e. soft, and rigid to create bio-inspired features). Some of these machines are: UltiMaker S5 (x2), Ultimaker 3, Raise3D Technologies Pro 2, Raise E2, JGMaker Artist D Pro.

Tool Changer 3D printer: Material extrusion machine with 4 separate print heads selectively picked by the tool changer head, and capable of extruding up to 4 materials together (E3D toolchanger).

Custom-made silicone 3D printer. A custom-made Material Extrusion machine capable of extruding magnetic ink at low layer thickness thanks to a custom-made electromagnetic system reducing the printing force. More details can be found here https://lnkd.in/d6Qpd55f

Microcoumpound machine: Machine equipped with two screws and real-time rheology control, capable of creating tailored filaments out of pellet, powder, nanotubes and so on. (Explorer Microcompounder M5)

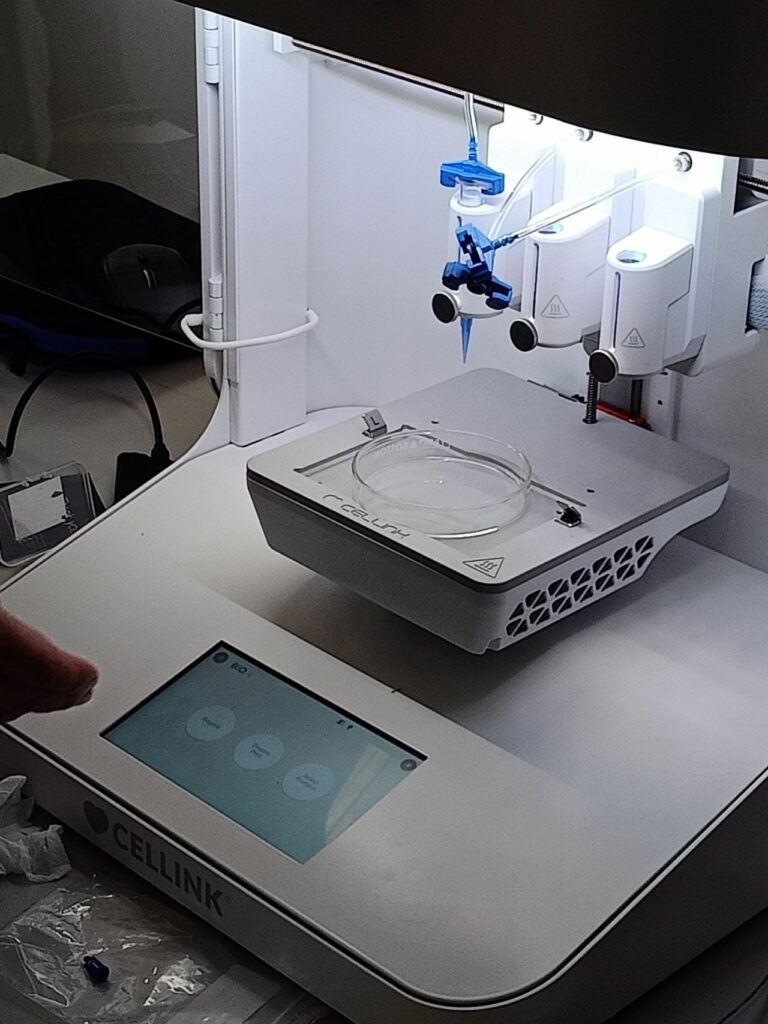

BioPrinter: Material Extrusion machine, equipped with three syringes capable of extruding up to three different bio-inks in the same manufacturing cycle. (BIO X BIOPRINTER CELLINK)

Ink-Jet Machine: High-performance ink-jet based machine capable of processing any kind of ink through orifices and dispensing droplets (on top of any kind of substrate) with a minimum dimension of 20 um (@MicroFab JetLab4)

Universal testing machine: Machine equipped with different load-cells to perform Mechanical Tests

INSTRON 34TM 10

Universal testing machine: Machine equipped with different load-cells to perform Mechanical Tests (tensile, compression, bending and so on) on a myriad of materials ranging from rubber, to high performance composites

Data sheet: download

MicroFab JetLab4

Ink-Jet Machine: High-performance ink-jet based machine capable of processing any kind of ink through orifices and dispensing droplets (on top of any kind of substrate) with a minimum dimension of 20 um

Data sheet: download

Microcompounder M5 Xplore

Microcoumpound machine: Machine equipped with two screws and real-time rheology control, capable of creating tailored filaments out of pellet, powder, nanotubes and so on.

Data sheet: download

BIOX BIOPRINTER CELLINK

BioPrinter: Material Extrusion machine, equipped with three syringes capable of extruding up to three different bio-inks in the same manufacturing cycle.

Data sheet: download